Lockheed Martin

SSB Arabsat

This 24,000-square-foot renovation features a high and low bay with 100K cleanroom standards for manufacturing commercial satellites.

Littleton, Colorado

Lockheed Martin

G Squared Design

24,000

Strategic scheduling for satellite production

The Big Picture

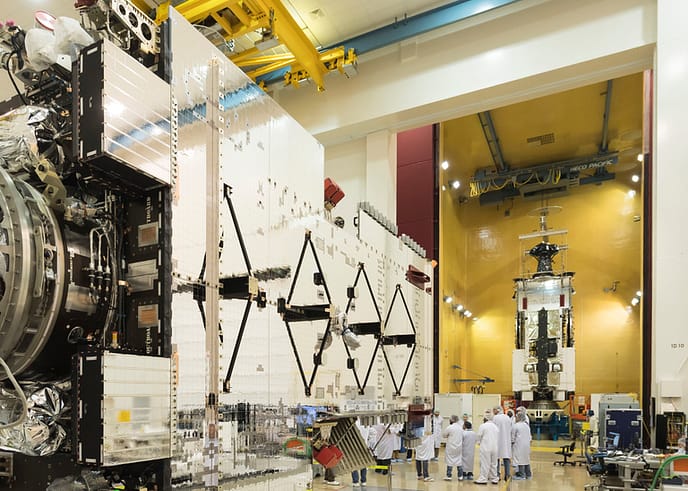

Lockheed Martin’s SSB Arabsat facility is used to manufacture satellites that will carry TV, internet, phone, and secure communications signals. The 24,000-square-foot space had to meet 100K cleanroom standards and involved the use of steel framing and cast-in-place concrete for the foundation and walls. The majority of the renovation took place adjacent to a 10K cleanroom, requiring extra care and construction logistics.

Strategically scheduled construction activities and integrated project delivery (IPD) contributed to an early completion with no safety incidents.

Ingenuity in Action

With tight design and construction timelines and 16-week lead times on some equipment, the schedule was packed into an overall construction duration of five months. With Lockheed Martin and structural and mechanical engineers involved in the planning from the start, the team worked together to complete the project three days early.

An unforeseen condition that required abatement was found early in the project, creating a six-week delay. Through collaboration, strategic planning and resequencing work activities, the impact was absorbed. The bulk of intrusive construction activities were scheduled while Lockheed Martin’s employees were off every other Friday, lessening the construction impact, and adding value and quality to the job.

An enormous amount of electrical, gas, and compressed air requirements were accommodated around the room. To avoid costly in-wall service runs, the conveyance of those utilities was organized behind a removable panel system developed by the team. The system allows flexibility for future modifications, prevented the need to modify the existing metal panel walls, and helped to maintain cleanroom standards.

The little details

- Air showers were installed at the circulation connections between 10K and 100K clean spaces in order to allow personnel to move from the 100K to the 10K without regowning.

- An “air shower," or a room that sprays air across material, was added to help reduce dust particulates in the clean space.

- The end user equipment was installed into the finished space earlier than expected since the project was completed three days ahead of schedule.